Safety must be the top priority for museum display case glass, with any risk of spontaneous breakage completely eliminated, and outstanding physical protective performance ensured. The industry recommends laminated glass, whose composite structure of “glass + PVB/SGP interlayer + glass” ensures that even if impacted and shattered, fragments remain firmly bonded to the interlayer, preventing scattering or collapse, while also buying time for security response. The optical performance of glass is particularly critical in the museum sector, where top-tier performance allows artifacts to be presented in their true colors, achieving an “invisible glass” viewing effect. Our products adhere to the industry’s strictest standards for glass.

Low-Reflection Laminated Glass

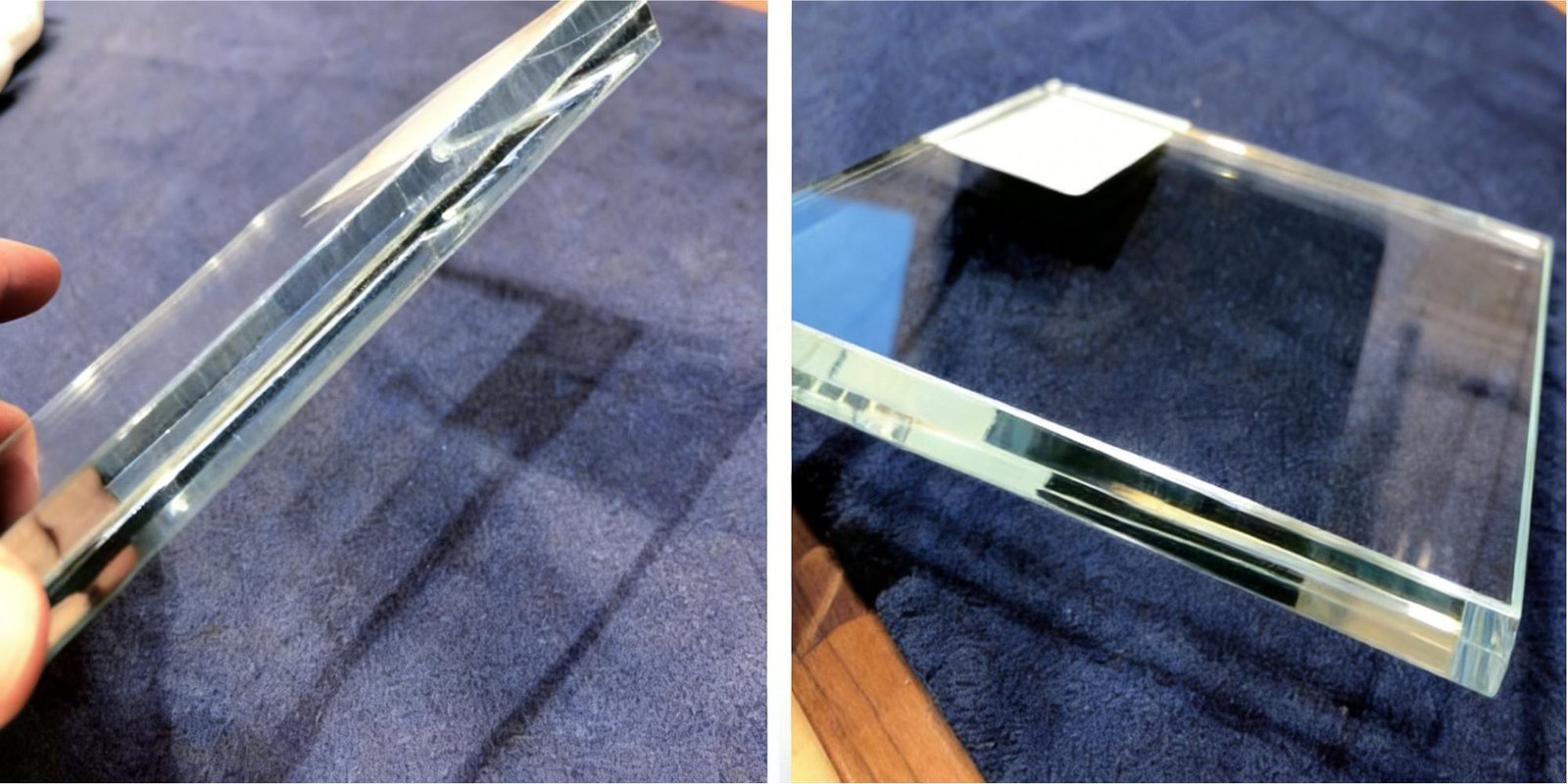

- Safety Performance: Utilizes laminated processing to eliminate the risk of spontaneous breakage associated with tempered glass. Mainstream options include ultra-clear laminated glass or low-reflective laminated glass. Thickness: Commonly employs a 6+0.76+6mm or thicker laminated structure, which passes impact tests such as the drop-ball test.

- Optical Performance: Low-reflective laminated glass reduces reflectivity to below 1% and increases light transmittance to over 97% through optical coating, significantly minimizing mirror-like glare and enabling more authentic color reproduction of artifacts (with a color rendering index of up to 99.3%). The glass must block over 99% of ultraviolet light (wavelength 320–380 nm), preventing light-induced aging damage at the source.